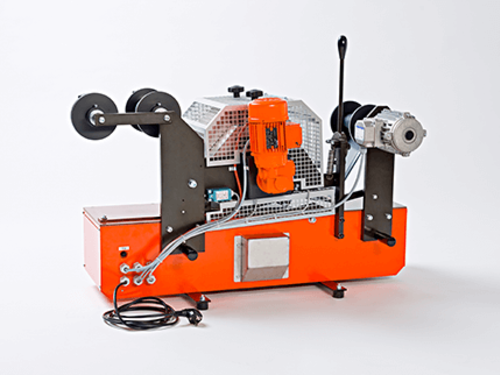

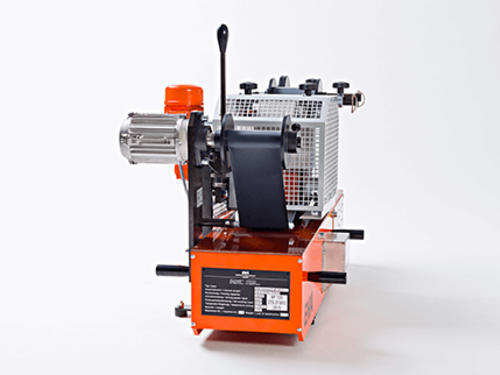

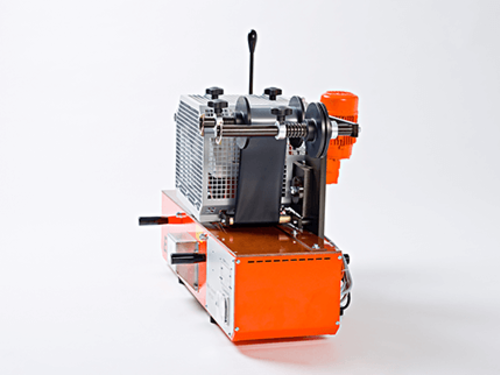

Hot Stamping Machines

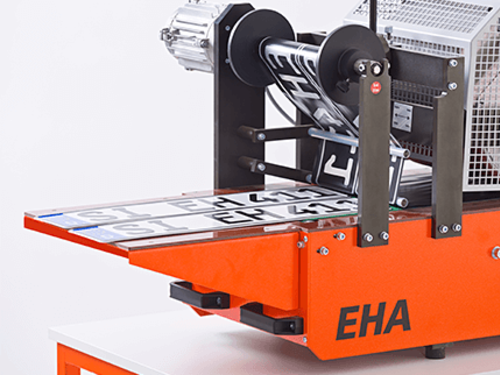

EHA Transprint HP 2010 – for clean and ecological-friendly production of motor vehicle license plates

- The EHA hot stamping machine allows clean and odour-free dyeing of embossed vehicle license plates in accordance with DIN74069 or ISO7591. The EHA Transprint 2010 features the latest technology combined with easy handling. The machine is equipped with many useful features that enables safe, economical and efficient production.

- Temperature display, temperature adjustment and language change functions as well as other parameters are set using the digital touch display.

- The integrated timer enables pre-programmed, individual operational availability. The hot stamping machine can be individually set for up to 7 days and 24 hours.

- The film saver function with deflection rollers ensures immediate separation of the ink coating from the base material (carrier foil). This results in a reduction of foil wastage.

- A cooling function allows the roller to cool down automatically, thus prolonging the service life of the machine.

- The machine is available in a variety of working widths, such as 120mm, 160mm, and 240mm.

Gallery

Benefits at a glance

- Operating temperature displayed digitally,

- Integrated timer,

- Economical film consumption,

- Standstill monitoring of rubber hot stamp cylinder,

- Automatic cooling function to allow cooling of rubber cylinder

Capacity

Approx. 400 plates per hour (for dimensions of 520x110)

Product information

Technical information

| Weight | 75 kg |

| Dimensions | W/H/D 875 (34.5") x 500 (19.7") x 335 (13.2") mm |

| Power source, power supply | 230 V, 50/60 Hz, 16 A |

| Heating power | 1300 W |

| Drive power | 90 W |

| Film reeling power | 60 W |

| Temperature control range | 0-220°C |

| Maximum operating speed | 5m/min, (16,4 ft/min) |

| Maximum working width | |

| Core power component axle | 25,4 mm (1") |

| Noise level | < 70 dB (A) |

Easy coloring of wide license plates

The EHA Transprint 2020 hot stamping machine was developed especially for dyeing wide vehicle license plates. Plates with widths of up to 220mm can be dyed in a single work step, or two plates with a width of 110mm can be dyed simultaneously. This increases your productivity and reduces your production time and costs.

You also have the option of fitting a plate conveyor belt to your machine. This transports the embossed plates through the hot stamping apparatus by way of a rotating belt, thus enabling fast and simple production of vehicle license plates. This function is particularly useful when producing license plates in large quantities, or for dyeing plates with no edging.

The machine is extremely powerful and is equipped with many useful functions that facilitate a fast, safe, and economical work process.

Temperature display, temperature adjustment and language change functions as well as other parameters are set using the digital touch display.

An automatic coasting cycle allows the roller to cool down, thus ensuring its long service life.

Gallery

Benefits at a glance

- Ideal for dyeing wide plates,

- Operating temperature displayed digitally,

- Conveyor belt (optional),

- Economical film consumption,

- Standstill monitoring of rubber hot stamp cylinder,

- Automatic coasting cycle allows cooling of rubber cylinder.

Capacity

Approx. 800 plates per hour (for dimensions of 520x110)

Product Information

Technical specifications

| Weight | ca. 130 kg |

| Dimensions | B/H/T 1700 (66,9'') x 580 (22,8'') x 670 (26,4'') mm |

| Power source | 230 V, 50/60 Hz, 16A |

| Heating power | 2200 W |

| Drive power | 90 W |

| Film reeling power | 60 W |

| Temperature control range | 0-220°C |

| Maximum Operating speed | 5m/min, (16,4 ft/min) |

| Maximum working width | 230 mm |

| Core power component axle | 25,4 mm (1") |

| Noise level | < 70 dB (A) |

Contact

We will be pleased to help

Waldemar Ginter

+49 271 39 32 - 0

Contact form

Claudia Müller

+49 271 39 32 - 0

Contact form